Description: Australia’s Railways

Discover how Australias railways compare with Japan’s Shinkansen and China’s high-speed rail. Learn about strengths, challenges, and prospects.

Introduction

Australia’s railway system plays a crucial role in the nation’s transport infrastructure, yet it faces significant challenges when compared to the world-leading systems in Japan and China. As the demand for efficient, fast, and sustainable transport grows, understanding these differences becomes vital. This article delves into the comparative strengths and weaknesses of these railway systems, highlighting opportunities for Australia to enhance its network through strategic investments and policy reforms.

Australias Railway System Needs Modernization

Coverage and Infrastructure

Australia’s railway network, while extensive, is a mix of modern and outdated infrastructure. Covering major cities and regional areas, it provides essential connectivity for passengers and freight. Urban transit systems like Sydney’s Metro and Melbourne’s tram network highlight significant investments, yet many regions still rely on older, less efficient systems.

Service Quality

Australia offers both passenger and freight services. Passenger services range from long-distance intercity trains to suburban commuter lines. Freight services are crucial for transporting goods across the vast country. However, service quality varies significantly, with urban systems often facing congestion and intercity services lacking the speed and efficiency of their international counterparts.

Ownership and Investment

Passenger services in Australia are primarily under public ownership, ensuring accountability and service prioritization over profit. However, some rail freight services are privatized but use on public assets. This privatization raises concerns about efficiency, investment priorities, and the potential for service quality to be compromised by profit motives.

Passenger services in Australia are primarily under public ownership, ensuring accountability and service prioritization over profit. However, some rail freight services are privatized but use on public assets. This privatization raises concerns about efficiency, investment priorities, and the potential for service quality to be compromised by profit motives.

The Impact of Lagging Behind

Economic Implications

The inefficiencies in Australia’s railway system have far-reaching economic consequences. Slower and less reliable freight services hinder the country’s logistics capabilities, increasing costs for businesses and consumers. In contrast, Japan’s Shinkansen and China’s high-speed rail networks have shown how efficient rail transport can drive economic growth by improving connectivity and reducing travel times.

Environmental Concerns

Australia’s reliance on diesel locomotives in some areas contributes to higher carbon emissions compared to the electrified networks of Japan and China. This reliance hampers Australia’s efforts to combat climate change and move towards a more sustainable transport system. The electrification of railways is crucial for reducing the transport sector’s environmental footprint.

Social and Regional Disparities

The variability in service quality and coverage worsens regional inequalities. While urban areas receive help from modern transit systems, regional and remote areas often lack reliable rail services. This disparity limits opportunities for economic development and access to essential services in these regions.

Learning from Japan and China

Speed and Efficiency

Japan’s Shinkansen:

– Coverage: Japan’s Shinkansen network connects major cities with high-speed rail lines, supporting domestic travel and regional economic integration.

– Infrastructure: Renowned for its ultramodern technology, the Shinkansen features advanced safety measures, automated control systems, and precision-engineered tracks.

– Services: The Shinkansen offers frequent, punctual, and efficient service, with trains running at speeds up to 320 km/h. This efficiency is a model for improving travel times and reliability in Australia.

China’s High-Speed Rail:

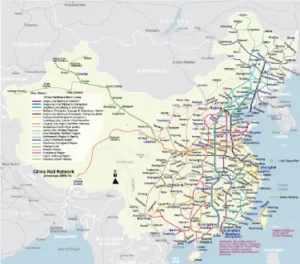

– Coverage: Boasting the world’s largest high-speed rail network, China rapidly connects major cities and regions, enhancing domestic travel and regional connectivity.

– Infrastructure: China’s high-speed rail infrastructure is modern and continuously expanding, incorporating advanced technologies and substantial investments.

– Services: Chinese high-speed trains reach speeds up to 350 km/h, providing a comfortable, convenient, and efficient passenger experience.

Technology and Innovation

Adopting Advanced Technologies:

– Digital Signalling and Automation: Australia can learn from Japan and China’s use of digital signalling and automated systems to enhance safety and efficiency.

– Modern Infrastructure: Investing in modern rail infrastructure, such as dedicated high-speed lines, will improve service reliability and reduce congestion on mixed-use tracks.

Public Ownership and Investment:

– Coordinated Investment: Emulating Japan and China’s public ownership models can ensure consistent funding, long-term planning, and prioritization of public interest over profit.

– Sustainable Practices: Investing in electrification and green technologies will reduce emissions and support Australia’s environmental goals.

Economic and Social Benefits

Enhanced Connectivity:

– Economic Growth: Improved rail infrastructure can spur economic development by enhancing connectivity between cities and regions, much like in Japan and China.

– Regional Development: Ensuring fair access to high-quality rail services can reduce regional disparities and support balanced economic growth.

Environmental Sustainability:

– Electrification: Transitioning to an electrified rail network will significantly reduce the carbon footprint of Australia’s transport sector.

– Green Technologies: Investing in sustainable infrastructure and practices will help Australia meet its climate goals and support global environmental efforts.

The Rise of China’s Maglev Trains

What are Maglev Trains?

Maglev (magnetic levitation) trains represent the cutting edge of rail technology, using powerful magnets to lift and propel the train along the tracks, eliminating friction. This technology allows for incredibly high speeds and smooth rides, making it a game-changer in the realm of high-speed rail.

China’s Maglev Development

High-Speed Innovations:

Shanghai Maglev: Currently, the world’s fastest commercial train, reaching speeds of 431 km/h (268 mph). This train connects Shanghai Pudong International Airport with the outskirts of central Pudong, providing a swift, 30 km journey in just over 7 minutes.

New Projects: China is developing new maglev lines to connect major cities, with plans for trains reaching speeds up to 600 km/h (373 mph).

Technological Advantages:

Speed and Efficiency: Maglev trains offer unparalleled speeds and efficiency, significantly reducing travel times between major urban centers.

Maintenance: With no contact between the train and tracks, wear and tear are minimal, resulting in lower maintenance costs and longer service life.

Environmental Impact: Maglev trains are powered by electricity, making them a cleaner alternative to traditional diesel-powered trains. Their energy efficiency is also superior due to reduced friction.

Potential for Australia

Adopting Maglev Technology:

Feasibility Studies: Conducting feasibility studies to explore the potential of maglev trains in Australia could be the first step toward revolutionizing the national rail network.

Strategic Routes: Identifying strategic routes where maglev technology could offer the most significant benefits, such as connecting major cities like Sydney, Melbourne, and Brisbane.

Investment and Funding: Leveraging public money to invest in maglev technology could position Australia at the forefront of rail innovation, providing long-term economic and environmental benefits.

Summary

Australia’s railway system, while extensive, faces significant challenges compared to the advanced networks in Japan and China. By learning from these leading examples, Australia can enhance its rail system’s speed, efficiency, and sustainability. Maintaining public ownership and investing in modern infrastructure and green technologies are crucial steps toward achieving these improvements. The economic, environmental, and social benefits of a modernized railway system will be far-reaching, supporting national development and reducing regional disparities. Embracing cutting-edge technologies like maglev trains could further propel Australia’s rail system into the future, offering unprecedented speed and efficiency.

Question for Readers

How do you think Australia can best improve its railway system to match the efficiency and sustainability of Japan and China’s networks, including the potential adoption of maglev technology?

Call to Action

Join the conversation on improving Australia’s railways. Share your thoughts and ideas using #AussieRailways #FutureOfTransport #RailwayInnovation. Visit our website for more information and to get involved in advocating for better rail services.

References and Further Reading

Japan’s Shinkansen Technology and Impact: https://www.railway-technology.com/projects/shinkansen-bullet-train/

China’s High-Speed Rail Developments: https://www.chinadaily.com.cn/a/202401/02/WS65937073a3105f21a507a12c.html

Australia’s Rail Infrastructure Investments: https://www.infrastructure.gov.au/infrastructure-transport-vehicles/rail

Environmental Impact of Electrified Railways: https://www.sustainabletransport.org

Australia’s Railway System Needs Modernisation

Coverage and Infrastructure

Australia’s Railway infrastructure was built between CE 1850 and about CE 1920 and this very quickly became the prime highly efficient land transport infrastructure, that wiped out the earlier technologies of Stage Coaches and Bullock Drays.

Originally, Australia was going to be the Irish 5’ 3” (1600 mm) gauge, as this was far more stable than the more common UK 4’ 8.5” (1435 mm) gauge, but because of the lack of large trees for sleepers and very long rail lines, QLD and WA and SA opted for 3’ 6” (1067 mm) gauge.

NSW started with 5’ 3” gauge, but with a change in Rail Managers (from the UK), the new line from near Central to Parramatta was narrowed to 1435 mm – primarily to conform to the UK Act of Parliament “outlawing” gauges other than Stephenson’s 4’ 8.5” rail gauge. Victoria wisely stayed at 5’ 3” rail gauge.

Almost all of this rail infrastructure was built using manual labour – and this why the rail lines wind around the hills / valleys instead of going straight through (as road highways after CE 1960 do. Through several decades this continual manual labour and mining and farming and grazing built generations of powerful / muscular / strong Australians.

By Federation in CE 1901, there was a very comprehensive rail network throughout most of Eastern Australia and in SA, and WA – and this was the backbone for Australia becoming a powerful nation. WW1 and WW2 “incidentally” wiped two generations of powerful Australian men – crippling Australia’s productivity until the CE 1970s.

By CE 1940 the Oil Industry Lobby (OIL) in the USA was finally brought to account for treason (in the USA) by buying up trams and busses and then closing down these infrastructures – forcing USA workers to purchase USA manufactured cars to travel to and from work (and buying / using far more gasoline in the process).

Circa CE 1950 the OIL had moved on from the USA to Australia and the OIL started to lobby / compromise Ministers / Senators to close down Urban Tram infrastructures and close down Regional Rail infrastructures. Why? Because the OIL knew that people using Cars and Busses (not Trams) and (diesel fuelled) Heavy Road Freight vehicles instead of (diesel fuelled) Rail Freight – the Oil industry would sell far more petrol and diesel fuel than ever!

Circa CE 1960 the OIL heavily compromised / lobbied Ministers and Senators / Executives / Staffers etc. at all levels to have new road highways built – using diesel powered mechanical aides – burning lots of diesel fuel in the process! (It should be absolutely no surprise that the current Tunnel Boring Machines (TBMs) use an immense amount of Diesel fuel and the OIL is right there too!)

By the CE 1970s most of the rail maintenance had been “let-go” leaving the (Regional) rail infrastructure to then rapidly fall into disrepair – and that was then very easy to “close” thousands of km of otherwise good railway lines and replace that highly efficient infrastructure with diesel fuel guzzling B-Doubles (that compared to Rail Freight uses about 3 times the amount of diesel fuel (as massive pollution) per equivalent load over the same nominal distance)!

From about CE 1980, Australia had a very thin skeleton of rail infrastructure – that deliberately (by continuous compromising by the OIL) to not have upgraded rail alignments to get rid of tight bends – preventing most Freight trains from travelling much over 40 km/h. Meanwhile the (unsafe) Truckies motto was/is “time is money”!

Compared to highway constructions – that use an immense amount of diesel fuel in the process), in most Regional localities it would be rather inexpensive to cut / fill and straighten some lengths (say 1 to 5 km long) of railway lines that would then facilitate the safe running of Rail Freight at 100 – 200 km/h – and use far less imported Diesel Fuel in the transport.

The Melbourne – Parkes – Brisbane inland rail is a classical example of the OIL committing treason in Australia. This project should have been completed within a couple of years of its concept (i.e. by about CE 2010) – but this programme has been really dragged out and repetitively de-funded while far less efficient road diesel fuel guzzling highways are being proactively funded. Go Figure!!

Service Quality

Ownership and Investment

The Australian Railways are not owned by the Government but mainly owned by the ARTC (Australian Rail Track Corporation) – which is a “competitive business” running / building / destroying / operating / maintaining / wrecking etc. an infrastructure.

If the Australian Railways were owned by the Federal Government, then this would be as a sub-Federal Department – called a Commission – for example: “Australian Rail Track Commission” (ARTC).

A Corporation operates as an “Competitive Business” (explicitly for discretionary products and services), where as a Commission operates as an “Infrastructure Business” (explicitly for essential products and services). These two business models operate literally 180 degrees opposite to each other – but utilise each other for both be highly efficient.

Western economics deliberately avoids teaching about how and why “Infrastructure Businesses” are inherently extremely efficient, because this learning deeply impinges on the greed model of corporations where the “rivers of infrastructure gold” are heavily diverted out of the infrastructure builds and into Senior Executives’ “renumerations” / shares and lost in grossly inefficient Bids and Tenders etc. that are generally very expensive minimalist provision strategies!

Each State has their own Rail Transport Corporation – making this infrastructure even more inefficient. Sydney has part of the rail network privately owned connecting to the airport – greatly damaging the economic efficiency of rail urban transport.

The Impact of Lagging Behind

Economic Implications

There is absolutely no doubt that the OIL has utterly wrecked Australia’s highly efficient long-haul rail network infrastructure and replaced this with a very high maintenance road network that is regularly wrecked by Heavy Road Freight vehicles – and maximises the importing and sales of diesel fuel into Australia at an enormous cost to Australia’s Balance of Payments (BOP) – which in turn internationally cripples the Au$$.

Given this drastic treasonous deliberate rail wrecked situation and the realisation that the Freight Rail cars are 8’ (2440 mm) in width, and that Passenger Cars were also 8’ (2440 mm) in width but are now merging to be 10’ (3040 mm) in width – it is really time to look at Australia’s rail infrastructure from a “future view” and not be tied up in ancient rail gauge technologies based on coal mines.

Circa CE 1835 a very eminent English Engineer: Isambard Brunel came up with a very sensible rail gauge of 7’ (2140 mm) to be used with the then standard 8’ (2440 mm) width cars – used for Passenger and Freight purposes. Not only was this “broad” rail gauge far more stable than all the other far more narrow rail gauges, but this 2140 mm rail gauge could carry a substantially heavier load – and the wear and tear on the infrastructure was far less!

This situation put a severe shock through the established “competing” railway businesses in the UK – and they colluded to arrange for an Act of Parliament to effectively call their 4’ 8.5” (1435 mm) to be “Standard” – and outlaw all the rest!

Considering that rail construction is now done almost robotically, it would be a very straightforward strategy to move to a longer (iron re-enforced) concrete railway sleeper capable of bedding the 7’ 0” (2140 mm) rail gauge; and an option of the 3’ 6” (1067 mm), or the 4’ 8.5” (1435 mm) or the 5’ 3.0” (1600 mm) rail gauges!

Concurrently use Australian manufacturing to manufacture bogies and wheels / axles to ride on the 7’ 0.0” and mount on the standard Cars. The more narrow rails would be left in place firmly fixed to the new “wide” sleepers to provide substantial extra support.

Now – trains using the “Standard” gauge may be (safely) limited to say 120 km/h – but the same train using the “wide” gauge bogie could then be (safely) limited to at least 220 km/h – if not 300 km/h – with the straight(er) alignment rails!

In other words, the trip between Sydney and Canberra (about 300 km) would take about 1h20m to about 1h30m (with a stop at Goulburn). The trip between Melbourne and Sydney (about 900 km) would take 3h45m (with a few stops on the way).

With an east-west tunnel under Blackheath and dual “broad” rail via the Grose Valley – and a “straightened” (dual) rail line, the trip from Parramatta to Orange (about 210 km when “straightened”) would take less than an hour! Aa trip from Parramatta to Gosford (when straightened and “Brooklyn Bridged” (100 m high)) would be about 58 km and take about 15 minutes. Parramatta to Newcastle (about 132 km) would take about 40 minutes! I have other sensible “Quick Rail” strategies for the other Capital cities – including Canberra!

The other economic concern is that much of this could be electrified – but Wind and Solar are far too unreliable and very expensive (when all the factors are included – not shown in so called “Nett Zero” falsified accounting) – and we have to go back to coal and or move to nuclear ASAP.

Environmental Concerns

The pollution from diesel engined Road Freight / Passenger vehicles is at least three times that of diesel/electric engine Rail Freight / Passenger vehicles.

Yes the thought of going to electrification has a nice “feel” about it – but Wind and solar are far too unreliable and very expensive – far more expensive than coal and nuclear.

Social and Regional Disparities

What is needed is dual tracks not single tracks so that several rail vehicles can follow each other in relatively quick succession instead of waiting hours for the single line to be cleared – We can very easily afford that!

Consider that Qatar and Australia are the biggest exporters of LPG and both export about the same amount of LPG.

Qatar receives $76 Bn while Australia receives only $2 Bn.

While new rail infrastructure goes in we need to put in 3 * 96 strand Single Mode Optical Fibre (SMOF) cables alongside the rail lines to provide regional connectivity that was “missing in action” when Telecom was privatised.

2024 06 16 Australia’s Railways – part 1

Thank you for your reply. I am sure much more could be done to make our rail system efficient if we had the political will. In Queensland when Joh Bjelke-Petersen was Premier he shut down many regional rail lines and promptly removed the track, I suspect so they could not be re-used in the future.